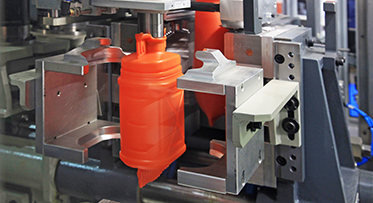

Rotational molding takes place when plastic materials are warmed and administered into an enclosed mildew to form the specified condition. Rotational molding has grown to be more popular then ever lately since it delivers numerous advantages, such as reduced-cost tooling, higher generation costs, superb fine detail duplication, and virtually no scrap fabric. In this particular blog post, we will review the reasons why Plastics Rotomolding is so well-known.

– Rotational Molding tends to make intricate shapes probable. For that reason, rotational molding is perfect for high-top quality manufacturing products that take time and effort to produce with other strategies, for example huge or sophisticated objects that need a number of different parts, and it’s also good for steel shot molds because the materials can be heated up rapidly attain increased output rates.

– Rotational Moldings make lower levels of scrap resources because of their accuracy and reliability and preciseness, so this implies much less squander overall when compared to conventional throwing procedures, by way of example.

– Rotational molds made from aluminium making it easier and less costly than before to produce tooling, in contrast to previously steel was needed, that means more expensive charges were actually incurred upfront – but now they’re not necessary! With Rotomolding, the molds are produced in much less time and cost than they could be along with other approaches.

– Rotational molding is flexible – it may generate products from an array of distinct supplies such as thermoplastics (e.g., polyethylene, acetal), thermosets (e.g., phenolics), or alloys and alloys (both ferrous and non-ferrous). Consequently Rotomolding delivers numerous types of feasible apps for every single kind of product or service imaginable!

– Rotational Shaped merchandise have excellent details replication, which makes them great for prototyping because they don’t call for costly instrument alterations to help make modifications to an thing under growth.

– Rotational molding is an eco friendly procedure since it uses less electricity to make a presented number of the fabric.

– Rotational Shaped goods are stronger than those produced by other approaches, and this means you can use thinner walls for your personal item which in turn minimizes excess weight, charges, and delivery troubles – all and keep strength. Rotoplastics even offers excellent substance level of resistance, so they’re great for food storage units or health care products.

Categories

Main Reasons Why Rotational Molding Is Indeed Preferred